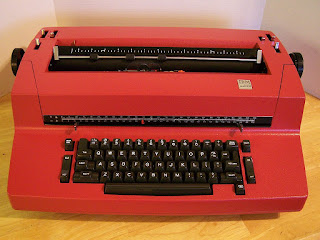

I just finished this IBM selectric 3 for a customer. It was a custom build because he wanted the Dvorak keyboard and the Selectric II style ribbon in Marlin blue. This machine came with the 210 bicycle ribbon and because it is harder to locate these days it makes sense to change it to the more available Selectric II style ribbon.

The keyboard was also converted to DVORAK layout (American Simplified) per customer request. I've gone into great detail about how I convert these in other posts and go the extra steps of making the dual-impression system function properly. That requires modifying the velocity vane to interface with the proper low-velocity interposers once they are relocated.

In addition to these modifications, I did a thorough overhaul. It received a complete teardown and washout cleaning in solvent to remove old grease and gummed oil. Wear items were replaced and everything was relubricated with synthetic grease and oil.

Now I just need to get it ready for shipping to the customer. I have purchased double-walled boxes to protect it and I will use a board to bolt it down with bolts, washers and spacers so it doesn't move around inside the box or the metal covers. Keeping my fingers crossed as shipping companies are known to be rough with packages.